Making of MFH 1/12scale Fulldetail Kit : Day 2

This is the making guide of MFH 1/12scale Fulldetail Kit.

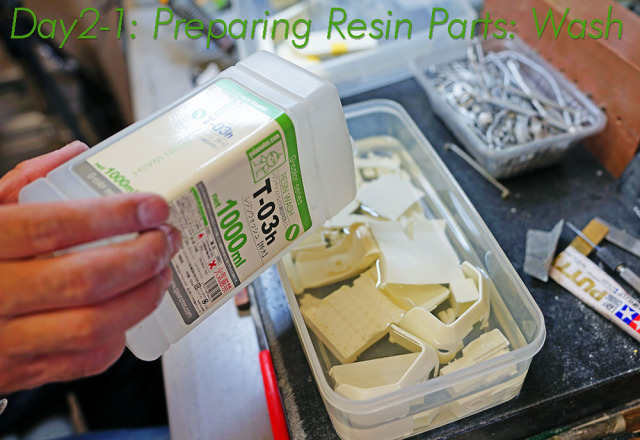

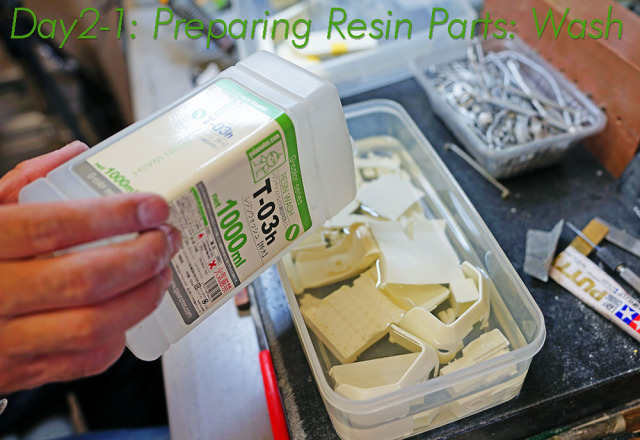

While MFH does not use release agents on our resin parts (so there is very little coating on the surface of parts), resin wash (third party item) is used to clean the resin parts to prepare them for coloring.

While MFH does not use release agents on our resin parts (so there is very little coating on the surface of parts), resin wash (third party item) is used to clean the resin parts to prepare them for coloring.

Sand off any imperfections for the resin parts. Use references on hand as a guide for what the shape should be.

Sand off any imperfections for the resin parts. Use references on hand as a guide for what the shape should be.

Certain resin parts have “variation” parts. After attaching please use putty to fill the parting lines between parts (use references to confirm if parting line exists or not for such parts).

Certain resin parts have “variation” parts. After attaching please use putty to fill the parting lines between parts (use references to confirm if parting line exists or not for such parts).

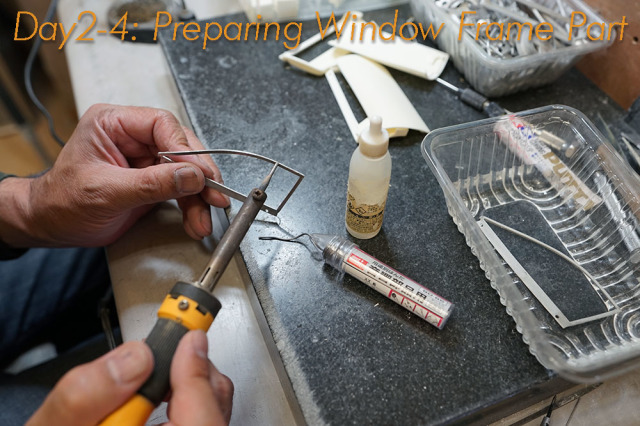

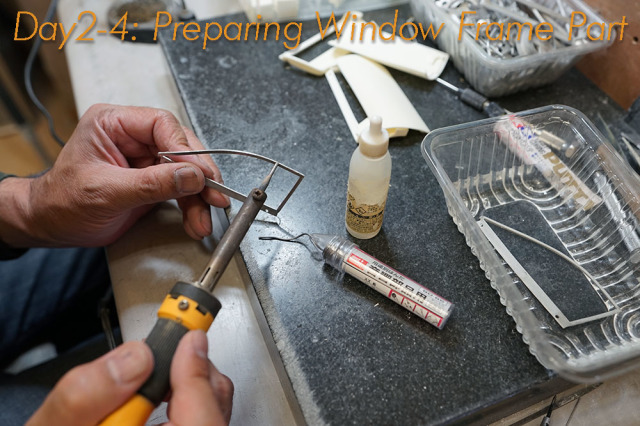

Use solder to attaching etching and metal parts together – while superglue can also be used, solder will create a strong bond between the parts.

Use solder to attaching etching and metal parts together – while superglue can also be used, solder will create a strong bond between the parts.

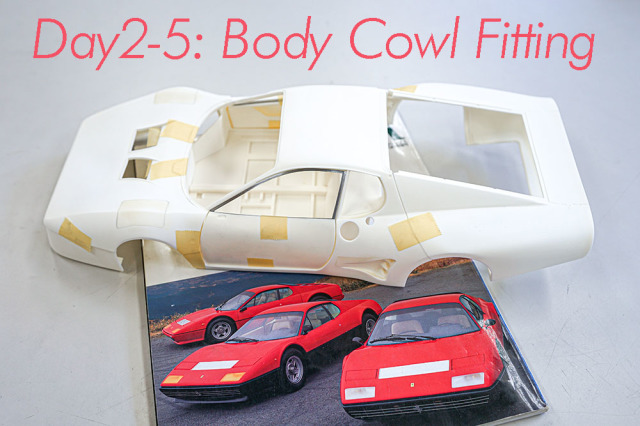

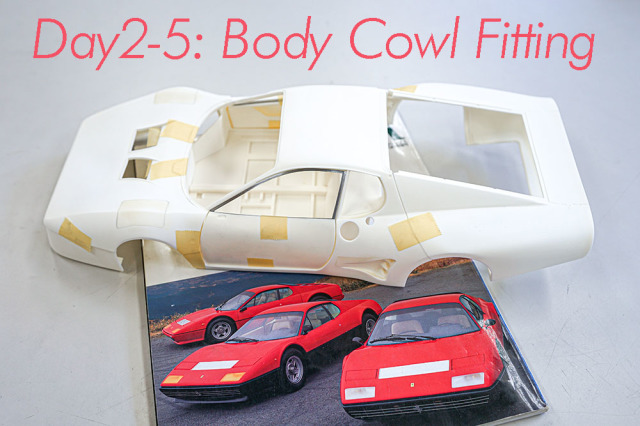

Make sure body cowl and parts around body cowl (such as window frames etc) fit together properly. Resin parts can be bended by a little if a small amount of heat (from a hair dryer etc) is applied to it.

Make sure body cowl and parts around body cowl (such as window frames etc) fit together properly. Resin parts can be bended by a little if a small amount of heat (from a hair dryer etc) is applied to it.

While MFH does not use release agents on our resin parts (so there is very little coating on the surface of parts), resin wash (third party item) is used to clean the resin parts to prepare them for coloring.

While MFH does not use release agents on our resin parts (so there is very little coating on the surface of parts), resin wash (third party item) is used to clean the resin parts to prepare them for coloring.

Sand off any imperfections for the resin parts. Use references on hand as a guide for what the shape should be.

Sand off any imperfections for the resin parts. Use references on hand as a guide for what the shape should be.

Certain resin parts have “variation” parts. After attaching please use putty to fill the parting lines between parts (use references to confirm if parting line exists or not for such parts).

Certain resin parts have “variation” parts. After attaching please use putty to fill the parting lines between parts (use references to confirm if parting line exists or not for such parts).

Use solder to attaching etching and metal parts together – while superglue can also be used, solder will create a strong bond between the parts.

Use solder to attaching etching and metal parts together – while superglue can also be used, solder will create a strong bond between the parts.

Make sure body cowl and parts around body cowl (such as window frames etc) fit together properly. Resin parts can be bended by a little if a small amount of heat (from a hair dryer etc) is applied to it.

Make sure body cowl and parts around body cowl (such as window frames etc) fit together properly. Resin parts can be bended by a little if a small amount of heat (from a hair dryer etc) is applied to it.